DG-750 Cable Peeling Machine 750W 1.5mm-38mm Electric Wire Stripping Machine Metal Tool Scrap Cable Stripper

Reliable shipping

Flexible returns

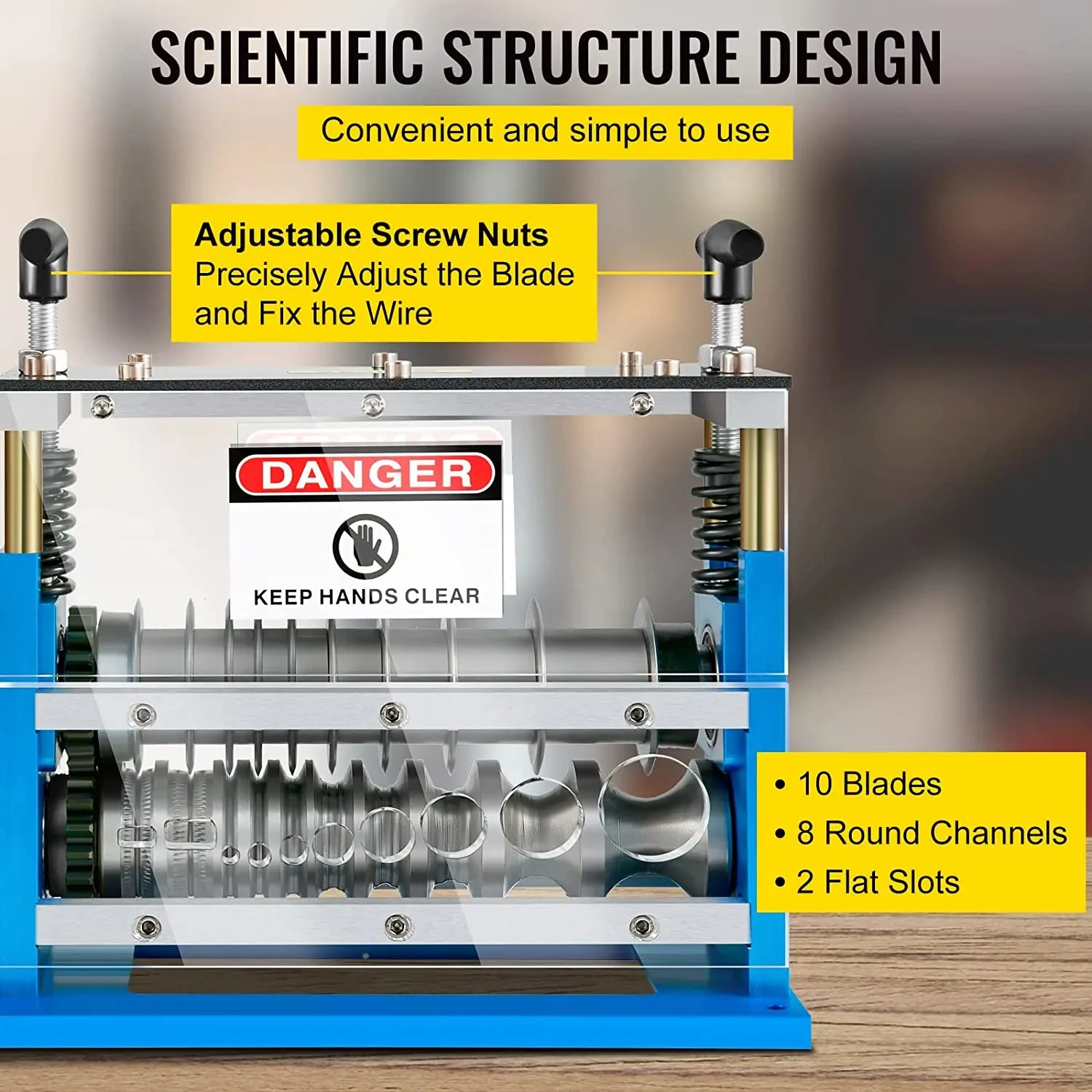

DG-750 multi-hole electric automatic wire stripping machine

Waste wires and cables are efficiently peeled and peeled

Say goodbye to tedious manual work and double the efficiency! The DG-750 is a powerful and fully automatic wire stripping machine designed for the recycling industry, which can easily handle the insulation stripping of all kinds of waste wires and cables.

Core specifications

Model: DG-750 Porous Electric Stripping Machine

Material: Aluminum alloy body, transparent acrylic protective cover, internal copper wire (refers to motor coil)

Core power: 100% pure copper motor

Rated power: 750W

Applicable voltage: 220V / 110V (strong global application)

Stripping diameters range: 1.5 mm - 38 mm (covering common cable thicknesses)

Number of feed holes: 10 holes (suitable for different wire diameters)

Stripping speed: up to 30 m/min (efficient continuous operation)

MACHINE WEIGHT: 27 KG (ALUMINUM ALLOY MATERIAL TO ENSURE STRENGTH AND CONTROL WEIGHT)

Dimensions (LxWxH): 47 cm x 29 cm x 37 cm (compact)

Applicable wire type

Flexible Cord (Rubber/Plastic Insulated)

Copper wire (single or multi-strand)

Aluminum core wire

Cables (small and medium)

Core Strengths & Features:

Efficient and fully automatic stripping:

Only need to feed the cable into the corresponding feed hole, and the machine will automatically complete the whole process of peeling, peeling, peeling and peeling.

Significant savings in time, manpower and operating costs, and a significant improvement in the efficiency of waste cable disposal.

Transparent & Lightweight Design:

Transparent acrylic protective plate: Clearly observe the internal stripping process and the running status of the wire, which is convenient for operation monitoring and simple maintenance.

Lightweight aluminium construction: While ensuring the stability and durability of the machine, the weight of 27KG makes it relatively easy to move or carry between stations.

Intimate safety and security:

Robust Protective Cover: Effectively isolates internal moving parts and reduces operational risks.

Emergency stop button: One-key quick shutdown in case of emergency, minimizing the possibility of accidents.

Protective design: Effectively prevent hands from accidentally sticking into the work area during operation, and improve work safety.